- About Us

- Sustainability Management

- Wholesome Foods & LOHAS

- Newsroom

Promotion Strategy

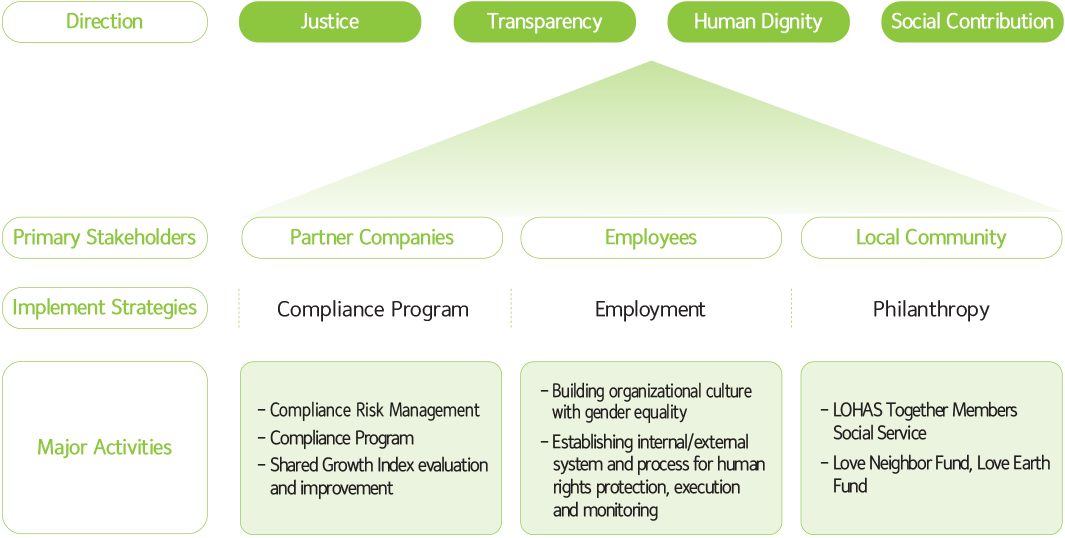

We contribute to the sustainable development of the society through inclusive business management that embraces all stakeholders.

Pulmuone has established and operated a standardized environment and safety system to realize the LOHAS value of caring for both humans and nature. The company periodically monitors air pollutants, chemical substances, waste discharge paths, greenhouse gas emissions, and waste discharges generated in the process of management activities. Pulmuone strives to minimize emissions by expanding environmental management facilities, developing eco-friendly packaging materials, and engaging in activities for environmental improvement.

Environmental Management Strategy

- Reduce water consumption from direct production by 50% against the baseline in 2008 (based on production/manufacture volume)

- Discharged wastewater quality enhanced 50% or more than the legal standard (production)

- Ensure discharge water quality is comparable to that of agricultural water (direct discharge site of river)

- Greenhouse gas emissions reduced by 35% against the level of 2008 (based on production/manufacture volume)

- Reduce energy usage by 24% compared to 2008 (based on production /manufacture volume)

- Reduce waster emissions

- Increase the waste recycling rate

- Animal welfare certify up to 20% of all eggs

- 100% solvent-free packaging

- Reduce waste discharge by 60% compared to 2008 (based on production/manufacture volume)

- Zero plastic packaging

Pulmuone’s ultimate goal for safety management is to ensure safety and health for all personnel in the process of carrying out management activities. To strengthen the analysis of causes and application of countermeasures by increasing the sensitivity of accidents, the company reports directly to the general CEO in the event of a disaster involving more than 1 day of work loss, and its partners also manage safety events based on the same standards. The company has also operated a corporate integrated environmental safety and health management system to prevent safety accidents, established a process of construction safety management from manufacturing facilities, and operated experience programs to increase training effectiveness. In addition, the company strengthens the operation of the subcontracting council and joint inspections to reduce the accident rate of partners, which are increasing in number. It also performs improvement activities along with risk assessment, and carries out a zero-accident campaign within the Pulmuone management area in the same manner as the company’s safety performance aggregation to support safety incentives by raising the prize amount in multiples.